Using lamination for more durable, secure ID Cards

A great way to make your ID cards more secure and have the image and print last longer is to include lamination into your ID card printing process.

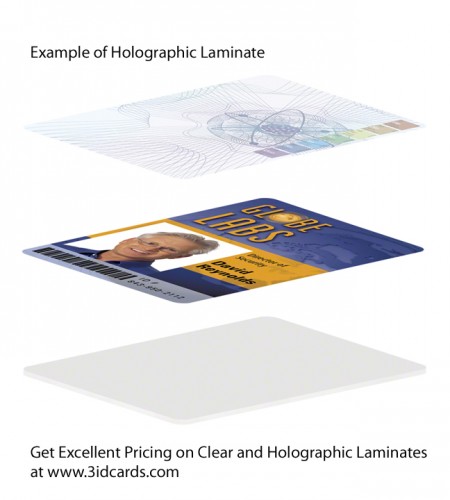

Let’s start off by discussing the lamination process and how it works. Lamination is a two-step process performed by a card printer with a laminator. The card printer prints on the retransfer ribbon or directly onto the card, known as direct to card printing. By adding lamination as a final step, the card has an instant protective film.

Laminators feature hot rollers that provide temperatures in the 280-375° F (140–190°C) range. With such temperatures, laminators actually “stick” the lamination material onto the card. You will need to use composite PVC-PET cards with your laminating printer. Composite cards are more resistant to the high heat used in the lamination process. Standard 100% PVC cards will warp during lamination, composite cards will not.

Your Basic Go-To Clear Overlays and Laminates

An overlay is also known as a topcoat or varnish. An overlay ribbon applies a clear thin layer (about .25 mil thickness) to the cards, edge to edge. They protect barcodes, signatures, logos and images against wear, fading and prevent dye re-sublimation. They will protect cards for 2 to 3 years and are recommended for applications requiring medium durability and minimal tamper resistance.

A laminate ribbon applies a clear protective polyester film to a card’s surface, making them more durable by providing protection against wear, fading, abrasion, moisture, chemical attack and forgery. Laminate thickness varies from .5 mil to 1.0 mil and can extend the life of the cards from 3 to 10 years. The thicker the laminate, the more durable the card. When it comes to laminate coverage of a card, there are a variety of laminate types. Some laminates cover the entire surface of the card while others cover a specific area and are referred to as patch laminates. A patch laminate is used when you want to laminate half of a card, a magnetic stripe card or a smart card.

Maximize Security with Holographic Lamination

A holographic laminate gives an ID card a high level of protection by adding visual security elements. The optical images of the ribbons are shiny, very high definition and 3D animated. These laminates provide a very high resistance against counterfeiting because it is not possible to duplicate a hologram with a scanner or a color photocopying machine and it is not possible to manufacture or copy a hologram through standard printing processes.

You have two options when it comes to holographic laminates: standard and custom. Standard holographic laminates are available in the open market and do not offer the same level of security as a custom holographic laminate. Fargo, Evolis, Datacard, Magicard, Zebra and Nisca all offer standard holographic laminate designs. Custom holographic laminates offer the highest level of protection against ID card counterfeiting and tampering.

If you need help selecting a laminating printer or you would like more information on designing a custom holographic laminate for your organization, contact 3iD’s identification specialists at 1-800-316-7304 x 2 to discuss your options.